Shielded Cameras

Shielded Camera & Audio systems

For indoor environments where high electro-magnetic fields are present and require visual monitoring, Castle Microwave is able to supply shielded camera and audio equipment.

Shielded cameras can be used inside chambers to monitor equipment being subjected to radiated signals to high levels of V/m during EMC testing, or in HVDC (high voltage direct current) converter halls in power station installations as part of site safety measures.

IR Thermo Cameras are an also an option. Used to detect Infra-Red images, with fixed lens (custom on request) it’s possible to see if equipment is running hot and possibly going into failure mode

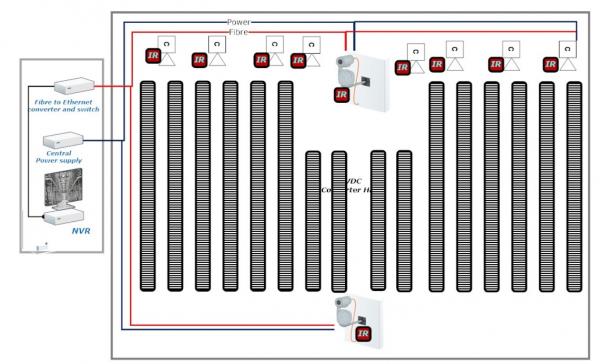

In addition to shielded cameras, audio systems are also available to provide an intercom to enable communication between the control room and chamber/converter hall.

A full range of products are available to provide a system solution designed to meet your unique requirements.

CCTV for EMC Test Facilities

Key features of shielded cameras for EMC applications:

• EMC shielded housing

• Specially filtered power supply

• Signal transmission via fibre optic cable assemblies

Consequently the emissions of the cameras are below the standard limits (CISPR 25) and the immunity is above the usual requirements (tested according to ISO 11452 to 200 V/m, and meets CISPR 22).

The quality of the lens and the CCD chip in the camera module are crucial for a good surveillance system, in order to provide the best possible resolution and light sensitivity.

We offer cameras for all kinds of applications, from small manual cameras to HD-cameras with IP control via network. The range extends from field strength cameras (HIRF) to cameras that can even withstand the nuclear electromagnetic pulse.

The audio intercom can easily be combined with the CCTV systems or provided as a stand-alone system depending on your requirements.

Surveillance in HVDC converter halls

Although fire detectors are mandatory in converter halls, use of visual surveillance is becoming more widespread due to the availability of shielded cameras and contribute to the safety of the site, e.g. hazard detection and fire emergencies:

• Detect hazard before it is serious

• Remotely identify if parts have fallen onto the converters

• Identify if parts have become damaged due to heat or failure

• Detect cooling system leaks/failures with the optional IR-Thermo camera

In case of a fire alarm:

• Check if the alarm is real without leaving the safety of the control room

• See what is burning and where